Remington 870 Tactical Shotgun Build

Build details

Tactical Remington 870 Build

UPDATE: To improve patterning, see our post on lengthening the forcing cone and back boring here

UPDATE: Scattergun Technologies Trak-Lock II Sight Installation is here

UPDATE: Vang Comp Systems ghost ring sight installation is here

Rifleshooter.com and Brownells team up to rebuild a neglected 870 express into a top tier defensive shotgun

Editors Note: The following documents a Remington 870 conversion and is presented for information purposes only.

Editors Note: Wear appropriate eye protection when working with tools.

Brownells provided the following tools and parts for this project:

Sage ghost ring sights, tritium front- note: you must measure your barrel diameter 819-200-880

Barrel vice jaws for drilling above 795-015-100

Speed Feed 870-L reduced length stock set 838-000-009

Scattergun Technologies 2 shot magazine extension 800-730-080

Remington metal shell plate (trigger guard assembly) to replace plastic 767-000-501

Extractor to replace MIM 767-161-760

Extractor Plunger 767-174-320

Extractor Spring 767-174-330

Jumbo safety 800-100-002

VTAC Sling 100-005-407

VTAC Sling Adapter 100-000-670

870 Service kit 080-870-010

Introduction

I have been an Remington 870 guy since I was 18-years old. I had been saving up and finally bought a Remington 870 “Police Magnum” with top folding stock from my local dealer. The 20-inch barrel with rifle sights were complimented nicely by the extended eight shot magazine and corn cob forearm. My friend bought the exact same model, we had exquisite taste.

I remember the first time I shot it like it was yesterday. At the time, the stamped metal folding stocking without a recoil pad and long length of pull seemed cool. My buddy and I enjoyed bruised shoulders and cheeks. We looked forward to saving up enough money to buy a case of cheap bird shot and heading out to the sand pit to shoot 250-rounds at a time.

Times have changed, I still own the same gun, however, it looks very different. The stock has been replaced with a standard fiberglass model. The 20-inch rifle sight barrel has been cut and crowned to 18.5″ and a set of ghost ring sights has been installed. The gun shoots better and is a pleasure to own, but I held onto that folding stock and still pull it out from time to time.

If you stop by your dealer and price out an 870 today, you will be impressed with the wide range of models available. The 870 Wingmasters, Police, Express and Express Tactical models make for an expansive line up. You will also notice the relatively high premiums commanded by the Police guns. These guns come off of a separate assembly line, use bar stock parts and are subject to extensive quality control inspections.

A while ago, I figured out it was cheaper and far more interesting to buy used 870s and rebuild them. Sometimes I buy police department trade-ins from various online dealers, but the supply is intermittent. Lacking patience, I also check local dealers looking for guns in poor condition for a fair price. Recently I found one.

If you never rebuilt or customized a firearm, a shotgun is a great place to start. Most of the upgrades are fairly simple to perform and cost less the tricking out an AR15.

Base gun

Our base gun for this build is a Remington 870 Express built in 2006 with a wood stock set. This gun has a plastic trigger housing and the now discontinued “J-Lock” internal locking mechanism safety. The magazine tube is not dimpled, and shows evidence that the previous owner must not have been very sophisticated, the base of the magazine extension is covered in gouges where he tried to tighten it with pliers. Mechanically the gun appears to be in good condition. I paid $160 for the gun.

This is the project gun, a 2006 Remington 870 Express. Note the black plastic clamp to mount a laser on the front.

The lack of wear on the bolt finish indicates this gun was not shot a lot. However, the bolt face indicates it was test fired.

The knurling was damaged with pliers by the previous owner

Initial Disassembly

You need the right tools to complete the job, this is especially true when working on firearms. For this project I will be using the Remington 870 Service Kit from Brownells. This kit contains everything the professional gunsmith, armorer. or serious hobbyist needs to disassemble, maintain, repair and reassemble a Remington 870 shotgun. A complete listing of what is included in the kit is available here.

Everything you need to work on a Remington 870 in one box

Have a storage plan in place before starting firearm disassembly. Firearms are loaded with small pins, bearings, detents and springs. Replacing lost parts is an expensive and time consuming process. Use a plastic storage container and small parts bags to keep track of parts as they come off the gun. If the plan is to replace a part during the rebuild, stow it in a separate area.

The build begins by ensuring the shotgun is safe and empty.

Check the chamber twice!

Ensure the magazine is empty

I remove the magazine tube, spring and follower.

Removing the magazine clamp

Now I can remove my mangled magazine extension

The magazine spring and follower say good bye

The factory Remington magazine tubes are secured to the barrel via a clamp. Once this clamp is removed you can unscrew the magazine extension and remove the follower. Since I am replacing these parts, I will store them in a separate location. With the magazine tube removed, I open the action slightly and remove the barrel.

Barrel is off

Next, I remove the slide and bolt assemblies by depressing the shell stop. Shown in next photo.

Depress this shell stop, below the orange follower and to the right of the shell plate to release the bolt

Slide the bolt assembly out of the front of the gun

Using the fore end wrench from the service kit, I unscrew the nut that holds the wooden forearm in place.

This is the best designed fore end wrench I have ever used

Plenty of working room and the tool does not bind

Then I screw the nut back onto the slide assembly so it isn’t misplaced.

I have misplaced these forearm nuts in the past, now I keep them together

Using a screw driver remove the two screws securing the recoil pad to the stock.

Then use the butt stock bolt wrench to remove the screw attaching the stock to the receiver.

This is the socket for the stock dis-assembly tool in the Brownells 870 Service Kit. It makes disassembly and reassembly a breeze, far easier then a screwdriver.

This is a quality tool

The tool head is basically a flat blade screwdriver captured by a rim. This prevents the tool from slipping.

The stock tool at work

If you are removing a wooden stock you will notice a small metal plate in between the stock and receiver. This prevents the stock from splitting under recoil, it will not fit in place with many new synthetic stocks. Secure the loose pieces. Reattached the recoil pad to the stock so you don’t lose it. If you are not reusing the stock screw, leave that in the stock as well so it isn’t misplaced

.

Using a punch, I remove the two pins from the shell plate assembly and remove the shell plate.

The gun is now disassembled.

These are the parts we are keeping

These are the parts we aren’t using, I will keep them together in a bin

I keep my parts together in a bin so I don’t lose them

Sight selection and installation

Most shotguns are equipped with either a basic bead (like ours when we started), rifle, or ghost ring sights. Beads are fast but lack accuracy. Rifle sights are far more accurate, but many shooters find them slow. Ghost ring sights give you the best of both worlds.

In the past I have used Scattergun Technologies and Trijicon ghost ring sight sets. UPDATE: Scattergun Technologies Trak-Lock II Sight Installation is here They are nice, simple, and easy to install. They do have some critics though. One of the criticisms of the Scattergun Technologies Sights is the attachment method of the front sight. The front sight is epoxied over the bead base and then cross pinned via a 1/16″ roll pin drill through the sides of the sight and the base. I have found this to be a satisfactory system and have never had one come apart. I recently tried to remove a front sight from a gun Scattergun Technologies built in the mid 90s, after I drifted the pin, I hit the front sight with a hammer- it didn’t move. I guess it is good to periodically try new things, for this build I selected Sage Ghost Ring sights.

On the Sage sights, both the front and rear sage sights are winged, unlike the Scattergun Tech. The front sight is solid metal. The tube at the base of the front sight is forced over the barrel and then set with a screw. This is a robust method of attachment. The rear sight, as with most systems, is secured to the receiver via two screws. Overall the sights appear more rugged then the Scattergun Technologies. The set shown also has a tritium insert in the front sight for low-light use. Note, you must measure the diameter of your barrel to select the proper sight set from Sage, they are press fit as well as screwed in place.

Sage Ghost Ring Sight kit- very heavy duty

Tritium insert on front sight. Note the threaded hole behind the sight wings, a screw passes through this and is drilled and tapped into the barrel.

Bottom of front sight assembly. Note split, this allows front sight assembly to be press fit over your barrel

Front sight next to barrel. We need to remove the bead base

Sage Ghost Ring Sights do NOT come with installation instructions. No problem, who reads instructions anyway. For this installation I am using a small milling machine. A drill press and vice would work fine as well. The Sage sights require the installer to drill and tap three holes. One to secure the front sight assembly and two to secure the rear sight assembly.

Let’s start with the front sight. I begin by measuring from the front of the sight assembly to the center of the threaded hole used to secure it. Once I have determined that distance I mark the barrel and head over to the mill.

I use a countersink and piece of card stock to find the center of the barrel. When the card stock is level, I am in the center. Note I am securing the barrel in the vice with some barrel blocks, they are designed for an AR 15 but work perfect for an 870 (795-015-100).

Too far forward

Too far back

Centered!

Next, I align the top of the bead with the countersink to make sure the barrel is vertical.

Making sure the barrel is vertical in the mill.

I use the countersink to start the #29 drill for the 8-32 tap.

Using a countersink to make sure the drill doesn’t wander

Then drill the hole.

The drill is guided by the indent left by the countersink.

Now I need to remove the bead base. You could grind, sand, or heat it off. Over the years I have found a file is the easiest. Take your time and be careful not to remove material in front of the base. Since the sight is pressed over, any flat spots on the crown will be visible when installation is complete.

Filing off the bead base

Nice and smooth!

Next, I use the nylon hammer from my service kit and start to push the front sight into place. Note: I did not use oil on the mating surfaces because I plan on refinishing the gun. Any trapped oil will become a problem during the refinishing process.

Starting to slide the front sight into place

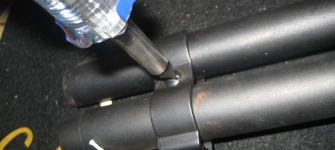

Notice the bottom slot expands as the sight is fitted to the barrel

I use an 8-32 tap to thread the barrel

I run a tap through both the sight and barrel to ensure the threads are aligned. Note: you will need to trim the screw that comes with the sights or you will have an obstruction in your bore

Now that the front sight is done, I can start on the rear. I begin by locating the front (8-32) hole for the sight. Since the sights do not come with installation instructions, I positioned the rear sight as far back as possible on the flat part of the receiver and center punched the front hole.

The receiver is secured in the vise. Once again, I begin my holes with the countersink to ensure the drill does not wander. Note brass jaws to prevent damage to finish

Using a #29 drill to drill the front hole for the rear sight

I then tap the 8-32 hole while the receiver in still on the mill. Once this is done, I attach the rear sight wings and locate the rear, 6-40 hole.

Tapping receiver

To cut screws to length I use a screw cutting fixture. The one I have didn’t have an 8-32 hole, so I made one from some scrap stock. This photo shows the screw cutting fixture for the 6-40 screw. It is hardened steel so you can file against it.

Screw fixture holds the screw

Thread the screw into the fixture so that the amount you want to remove is extending past the back side and file away.

I use blue Loctite in the stick form. I find the stick way easier to use then the liquid.

Loctite in a solid stick, it will change your life

Once the screws are trimmed so they don’t interfere with the action, I attached the rear sight to the receiver.

Rear sight base and protective wing assembly installed

I use the Magna-Tip screwdriver from the service kit to install the ghost ring assembly

Sights are installed

Upgrading MIM Parts

The extractor on this Remington 870 Express is MIM. While many find MIM parts serviceable, I have decided to proceed on the side of caution and replace the MIM extractor with a bar stock part (767-161-760). I will also change the extractor spring ( 767-174-330) and plunger (767-174-320) while the gun is apart.

Push back on the plunger with a screw driver and remove the extractor

This shows the plunger you need to push on. The extractor is removed in this photo.

Bar stock part is on the left, MIM on the right- notice the slightly different shapes

To install the extractor simply push down the plunger and insert the bar stock part

Stock Selection

For this build, I selected a Speedfeed short stock with a ribbed forearm. Over the years, I have found this combination to be especially fast handling. This stock has a longer length of pull then the short Hogue overmolded entry stock. While the Hogue stocks are perfectly serviceable, the Speedfeedand has a solid construction with an excellent rubber recoil pad.

Speedfeed reduced LOP stock set 870-L

To install the stock, you simply reverse the disassembly process from earlier.

Slide the new fore end over the slide assembly

Make sure it is fully seated

Put the fore end nut on your fore end wrench

Tighten

Fore end is ready to go. I lightly lube the rails

Place the new rear stock on the reciever

Use the stock tool to tighten it down, be careful not to over tighten, it can impede function of the action and trigger housing

Screw the new recoil pad on

It is time to start putting the gun back together. Since the barrel is already on the receiver, I assemble the bolt and place it on the slide assembly.

Ready to go back!

Be careful not to knock things out of alignment

Starting to look like a shotgun

Magazine extension

For this project we are using a Scattergun Technologies 2 shot magazine extension (800-730-080). The kit includes the extension with sling attachment, follower, and magazine spring.

Extension kit

Non binding follower. Note: If you use this follower in a factory Remington extension, it will bind

You can use a cleaning rod to guide the spring in, I normally don’t

Shell Plate

The trigger guard assembly is known as the shell plate. This gun had a plastic assembly, with weaker, Express springs. I would rather have a metal part with the stronger and no MIM parts. Brownells catalogs an entire Police model shell plate assembly shown below. Part number is 767-000-501.

Right side view. Police assembly is on the top.

Left side. Notice the now defunct “J-lock” on the plastic assembly

Back view

Safety I prefer an oversize safety on my shotguns. Changing them out is easy. I am using a Scattergun Technologies here (800-100-002)

Push the pin that retains the safety spring and bearing. Make sure not to lose any of the parts.

Go slow, watch the spring

The spring and pin are removed. The bearing normally will stay in the hole. Just slide the safety out

Oversize part is on the left for comparison purposes

Factory part is on the bottom

To install the new safety, slide the safety in and place the spring in the hole. Start the retaining pin and push down on the spring with a small punch while you slide the retaining pin back into place. You’re done

To reinstall the trigger guard I use the slave pin from my service kit to align the holes.

The slave pin makes pin installation easy

All done, this gun handles like a dream. With the addition of a VTAC sling, it is ready for duty. Next stop for this bad boy is the range and a refinish.

Parts List

Overview of the parts and tools we used in our build, we have provided Brownells parts numbers and a link to each part to make replicating your build easy.

Sage ghost ring sights, tritium front- note: you must measure your barrel diameter 819-200-880

Barrel vice jaws for drilling above 795-015-100

Speed Feed 870-L reduced length stock set 838-000-009

Scattergun Technologies 2 shot magazine extension 800-730-080

Remington metal shell plate (trigger guard assembly) to replace plastic 767-000-501

Extractor to replace MIM 767-161-760

Extractor Plunger 767-174-320

Extractor Spring 767-174-330

Jumbo safety 800-100-002

VTAC Sling 100-005-407

VTAC Sling Adapter 100-000-670

870 Service kit 080-870-010

build comments