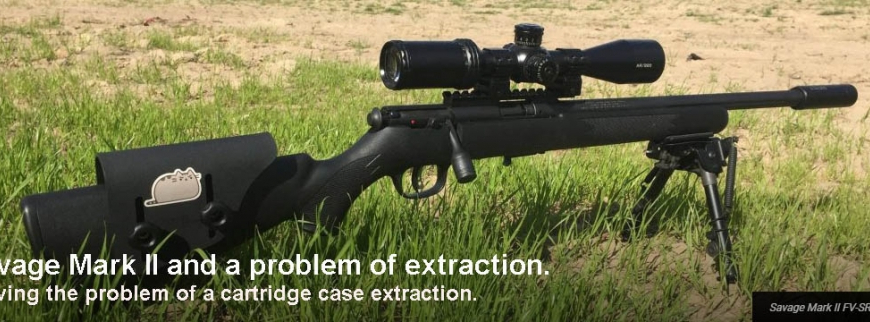

SAVAGE MARK II AND A PROBLEM OF EXTRACTION

Solving the problem of a cartridge case extraction.

A few months ago I bought this wonderful small bored - Savage Mark II FV-SR 16′. It was a tough choice but after doing some consulting I made my decision. There are some reasons why:

- Middle-long - with a suppressor A-TEC (it’s equipped with six cameras, I put down three of them, this is enough for work and it half reduces the size) it’s no longer than an average small-bored without a suppressor;

- Screw-thread for a suppressor from the box, and it costs about 100$;

- Branded ACU Trigger - the best solution for small-bored;

- Weaver rail mount from the box, it’s another 20$;

- Pretty good stock;

- Bigger bolt lift from the box;

- Awesome tactical barrel flutes.

Right after I purchased it, I revealed the cartridge case extraction problem. The interesting thing that it didn’t apply to all cartridges, some were extracted without any difficulties, others were stuck sometimes and some got stuck all the time.

In the beginning, I didn’t have a clue what I must do with this, so I asked my friend for help. Firstly, he took apart the bolt carrier group (BCG) and compared it with the others - rifles at the shop (I owe him a big thanks for that). We noticed nothing unusual. After that, the extraction started to function better and I assumed that it was an assembly issue, but some time later it appeared that the problem still exists. I made some research through the Internet and I scouted that this is the common issue and not only for Savage.

Here are the solutions which I managed to find:

1. To rebuild the BCG, the ejector, sometimes it could be built wrong or it’s impure (it’s the usual thing for shooters, they shoot for 5 thousand times and don’t clean it and then they complain that something doesn’t work);

2. To cut off a bit of an ejector jag (2) (it’s my choice, the details are below);

3. Write to Savage to get the new spring (3) - in this case, I mean the licensed service center or the service center which can get the ejector spring. Maybe these springs could be with defects or something else, no one has ever mentioned this. Some people wrote that the replacement has helped. Furthermore, one man did it at least two times straight, because the first replacement didn’t help.

Disassembling.

You can see partially disassembled BCG below, some moments haven’t shown in the Internet. I don’t claim my method of build/disassembling is being the only right one, but it’s my way to do it. I would like to pay your attention to the extraction layout as well - it must be located on the side of the cartridge case remove screen. If the ejector and the slide are reversed (sometimes it had happened) the cartridge cases won’t be released.

blog comments